NEW! ZeroFlame® Technology

Clean - completely without filters

The ZeroFlame® technology convinces through:

We would like to present the new dimension in pellet condensing technology

Thanks to the completely new concept of Condens condensing technology, the Pellematic Condens is the world's first pellet condensing boiler that can be integrated into any heat supply system. There is no need for a buffer cylinder either.

Its compact design, a small footprint the same size as that of a refrigerator and the intelligent, flexible arrangement of all connections make it adaptable to any boiler room.

Condensing technology means that the residual heat contained in the flue gases from pellet combustion is also harnessed.

Heating systems with condensing technology therefore utilise almost all the energy contained in the exhaust gases from pellets. This additional benefit of approx. 16.3% with pellets is simultaneously the energy saving made possible by condensing technology. This allows condensing boilers like the Pellematic Condens to achieve efficiency levels of up to 107.3%*.

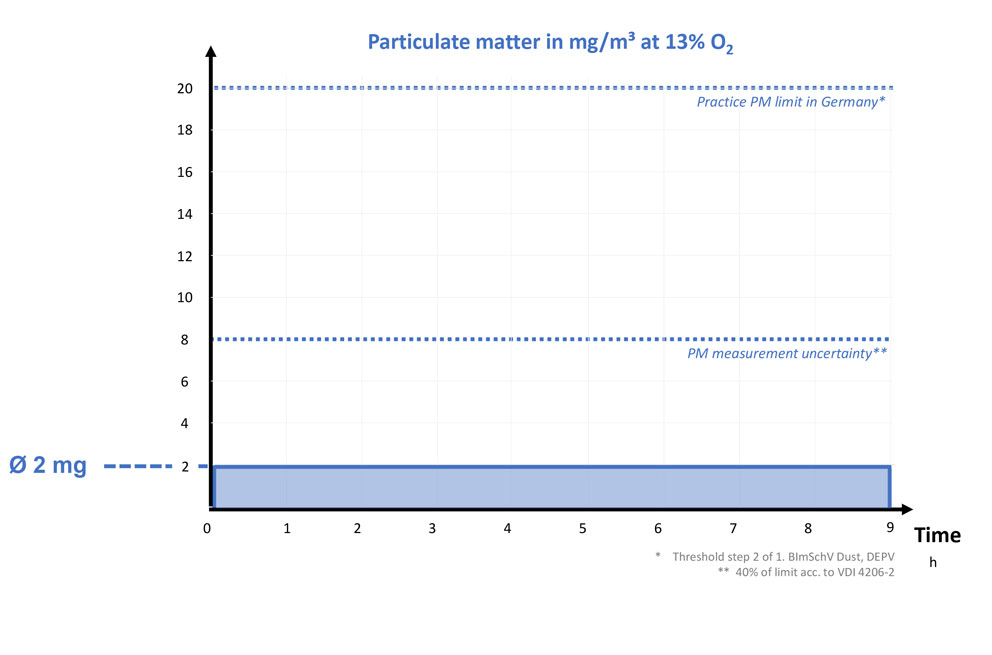

With the all new technology ÖkoFEN achieves dust emissions close to zero.

WITHOUT any filter technology.

Particulate matter and dust emissions are an ongoing issue in the heating industry.

For air pollution control and possible innovation incentives lower emission values are demanded. After years of intense work in our R&D department and a Europe-wide field test ÖkoFEN has succeeded in taking a big step towards absolutely clean energy conversion from wood pellets.

Why did we develop ZeroFlame®?

The aim was to develop a solution that would bring absolutely no restrictions to the previous technology in terms of comfort and reliability. Alternatively, electric high-voltage particle filters are used in the industry, but they are cost-intensive and rarely maintenance-free. So this option was soon discarded. As a result we continued to work on a better, simpler solution, which takes place directly in the combustion chamber.

How does ZeroFlame® work?

ZeroFlame® is a milestone in ÖkoFEN history.

The special-guided airflow and air-enrichment in combination with a special combustion chamber design leads to a very special effect. The flame disappears almost completely during combustion and reduces particulate matter to a minimum. All that remains is:

Cosy warmth and clean exhaust air!

Without ZeroFlame®

Regular combustion of pellets - with flame

With ZeroFlame®

ZeroFlame® Technology - without flame

ZeroFlame OFF/ON - direct comparison

In our web animation, you can switch the ZeroFlame technology on or off yourself by clicking on the ON/OFF button.

Wood pellet fire without flame!

The cleanest ÖkoFEN pellet heating system ever!

The cleanest ÖkoFEN pellet boiler ever

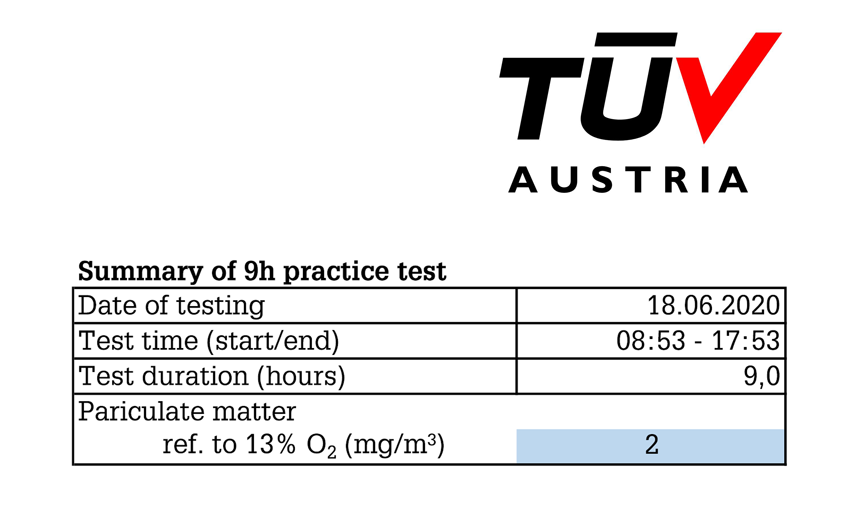

Tested by TÜV Austria

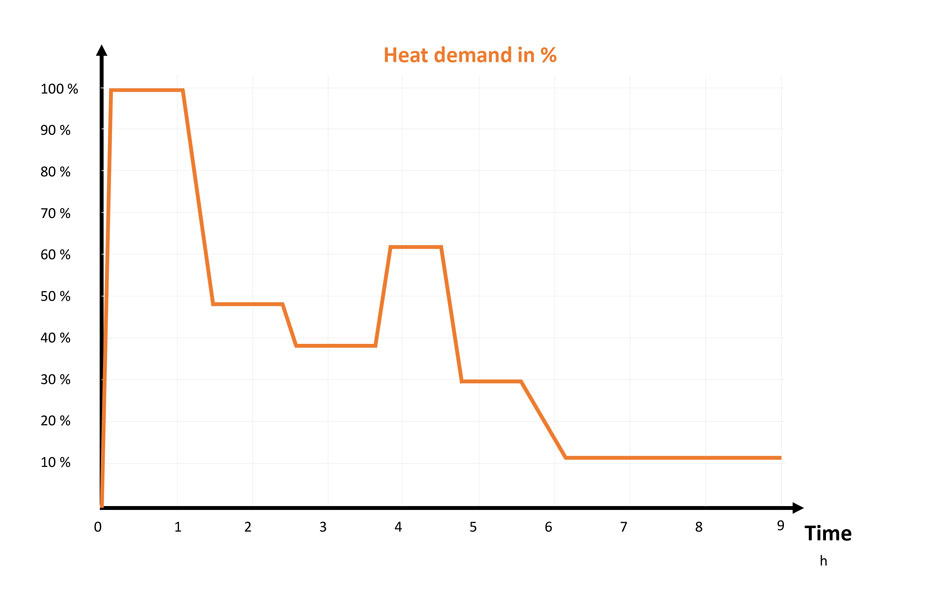

The amount of particulate matter leaving the high-efficient pellet heating system can hardly be measured. This has a high impact to the environmental situation worldwide. A practice 9-hour load cycle test carried out by TÜV Austria officially confirms the excellent values and unique effect of the new technology.

Practice load cycle test

The 9h load cycle test is a dynamic cycle test which represents real operation values of a heating system in our latitudes. This test is absolutely not comparable with other static test reports.

In the smallest output range, the emission test includes one start and two stops of the boiler.

Menue

Menue