Pellematic

Pellet boiler

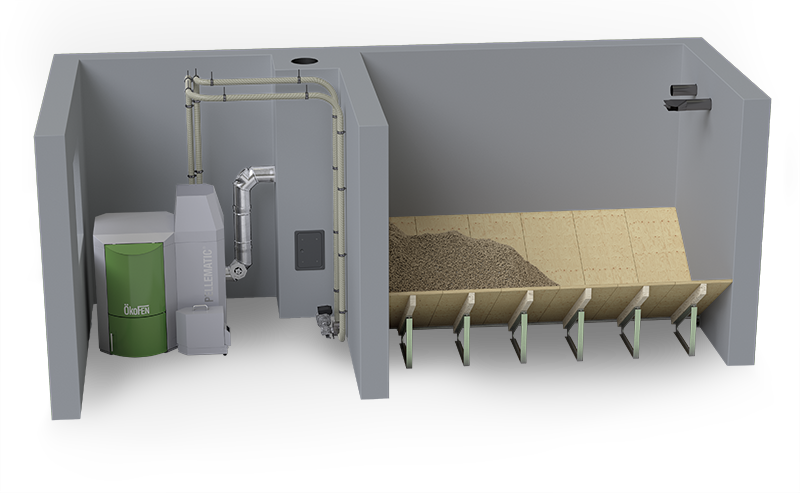

The ÖkoFEN Pellematic uses technology that has been tried-and-tested over years, impressing with both total reliability and the highest quality workmanship. It still represents the optimum heat exchange solution.

Convenience and technology of the highest standard

The boiler performance is tuned precisely to your needs with the Pellematic pellet boiler. This enables optimum utilisation of the heating system and low pellet consumption. If energy demand rises (e.g. due to an extension), the boiler output can be adjusted upwards within the power range. If energy demand falls (e.g. new insulation), the boiler output can be adjusted downwards.

Highlights of the Pellematic

The original – for over 20 years

ÖkoFEN launched the first type-approved pellet heating system in 1997. This was the beginning of a success story. The ÖkoFEN Pellematic uses technology that has been tried-and-tested over years, impressing with both total reliability and the highest quality workmanship.

The Pellematic offers the benefit of flexible adaptation to energy demand. If a subsequent extension of the building requires more or less heat, because additional insulation is installed, then a customer service engineer can adjust boiler output within the power range to meet current demand – complete boiler replacement is no longer necessary.

Pellet heating systems from ÖkoFEN have been clearly well below the upper limits of the Federal Emission Control Act (BImSchV) for years. ÖkoFEN makes a well-conceived, controlled combustion system possible with Efficient Combustion Control (ECC) technology. This ensures that heating with wood pellets knows no bounds.

The benefits of the Pellematic at a glance

The original ECC technology in detail

Matching articles for the pellet boiler

Technical refinements

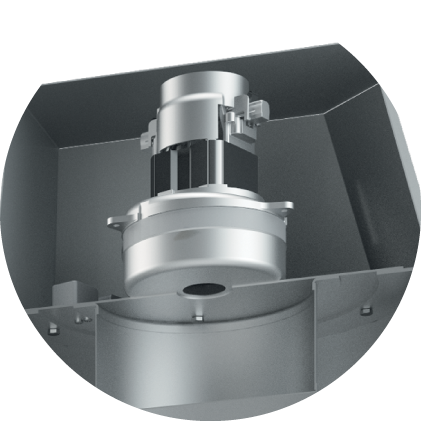

Vacuum turbine

for filling the hopper automatically

Straightforward maintenance and cleaning

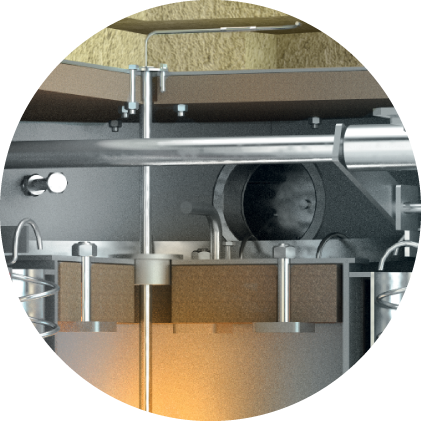

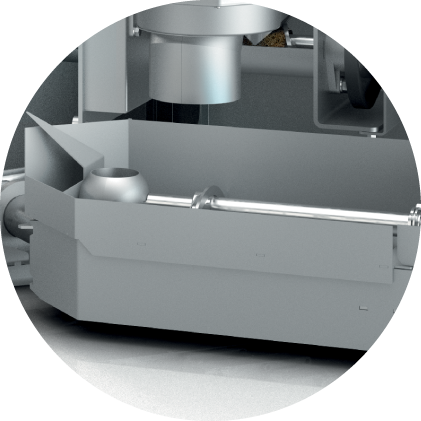

Integral return water temperature control

without costly technology

Negative draft control

Combustion chamber sensor

for automatic fuel detection

Hopper

for 45 to 60 kg pellets (depending on boiler size)

Fully automatic heat exchanger cleaning

Stainless steel combustion chamber

For quick achievement of the optimum combustion temperature

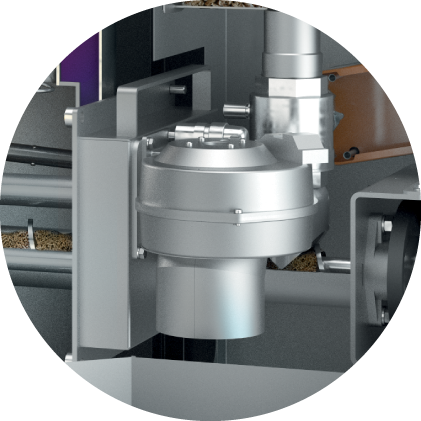

Multi-segment burner plate

Electronic ignition with glow rod

250 W output only

Proven burn-back protection

by means of ball valve

Air intake manifold

Comfort ash box

Dust-free ash removal with automatic notification when the box is full. (available as an option).

Fully automatic de-ashing system

The unique combustion technology developed by ÖkoFEN enables highly efficient combustion with low emissions, thanks to its three main components: multi-segment burner plate, combustion chamber sensor and negative draft control.

- Efficient Combustion Control technology

ensures low emissions, constantly high efficiency and optimum adaptation of heating output to the building's requirements. - Pelletronic Touch programming unit for intuitive operation

with touchscreen display and self-explanatory graphics. - Comfort ash box for dust-free ash removal (optional)

with compostable corn starch sack and automatic notification when the box is full.