Pellematic Maxi

Pellet heating system

The Pellematic Maxi builds on the proven technology of the Pellematic range and applies it to a 56 kW boiler. This makes it extremely popular, especially in the industrial and commercial sector, with hotels and local authorities, and in multi-storey residential developments.

The wood pellet boiler for large systems

Alongside its performance, the Pellematic Maxi can also score highly with other convenient solutions: The pellet heating system can also be equipped with a fill level monitoring option (available for all boiler types), and it features remote control, including automatic reordering of wood pellets, and an ash box as standard. A convenience otherwise normally found only with pellet heating systems in private households.

Highlights of the Pellematic Maxi

A strong team for even more power

In terms of technology and convenience, the Pellematic Maxi large boiler features all the proven benefits of the Pellematic range, such as the comfort ash box as standard, ECC combustion technology and flexible output adjustment.

For greater heat demand, the Pellematic Maxi can be configured as a cascade. This allows output of up to 224 kW to be achieved with up to 4 boilers.

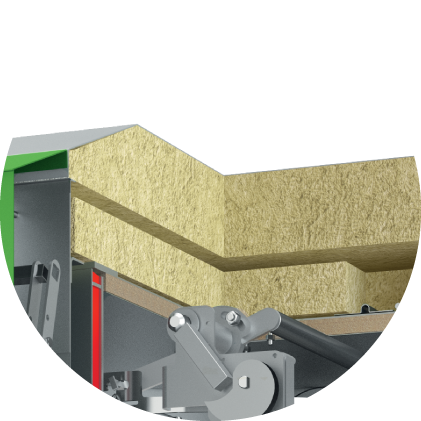

A vacuum suction system transports the pellets carefully to the heating system, whereby the large boiler can be supplied with pellets from either a Flexilo storage tank or a storage room. In a multi-boiler system, the fuel feed is separate for each boiler.

The Pellematic Touch controller allows the heating system to be accessed conveniently from a computer or smartphone and all data to be called up at any time. The mobile user interface is just as clearly designed as the control panel on the boiler.

Thanks to its compact dimensions, the Pellematic Maxi fits through doors as narrow as 80 cm, so the pellet heating system can be installed without any costly construction work.

A vacuum suction system transports the pellets carefully to the heating system, whereby the large boiler can be supplied with pellets from either a Flexilo storage tank or a storage room. In a multi-boiler system, the fuel feed is separate for each boiler.

The Pellematic Touch controller allows the heating system to be accessed conveniently from a computer or smartphone and all data to be called up at any time. The mobile user interface is just as clearly designed as the control panel on the boiler.

Thanks to its compact dimensions, the Pellematic Maxi fits through doors as narrow as 80 cm, so the pellet heating system can be installed without any costly construction work.

The benefits of the Pellematic Maxi at a glance

Matching articles for the pellet boiler

The technical refinements

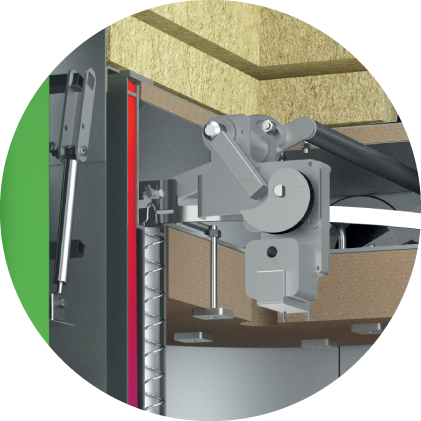

Vacuum turbine

for filling the hopper automatically

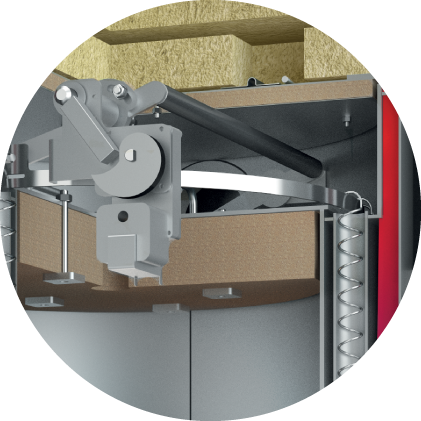

Simple access for maintenance and cleaning

Integral return water temperature control

without costly technology

Negative draft control

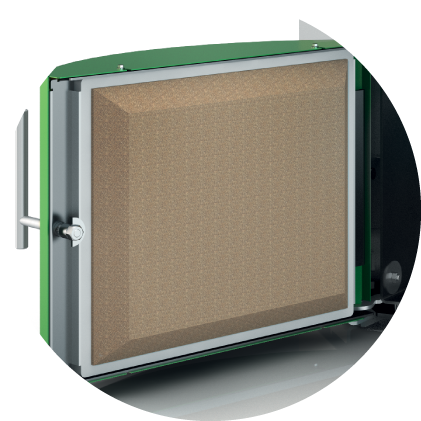

Hopper

for 70 kg pellets

Combustion chamber sensor

Fully automatic heat exchanger cleaning

Proven burn-back protection

by means of ball valve

Electronic ignition with glow rod

(250 W output only)

Multi-segment burner plate

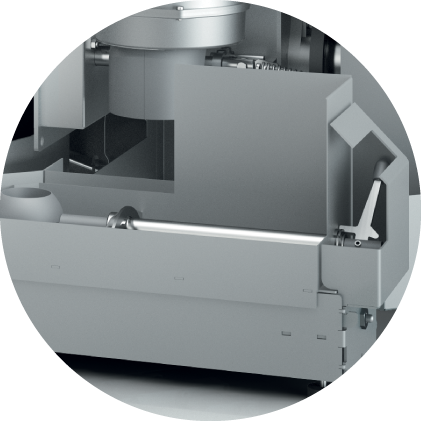

Comfort ash box

Dust-free ash removal with automatic notification when the box is full.

Fully automatic de-ashing system

Simple access for maintenance and cleaning

The compact heating system for large-scale requirements. Economical, powerful and convenient.

- Efficient Combustion Control technology

The technology comprising a multi-segment burner plate, negative draft control and combustion chamber sensor ensures low emissions, constantly high efficiency and optimum adaptation of heating output to the building's requirements. - Multi-segment burner plate for greater functional reliability

features individual segments to prevent stress, while ensuring low spare part costs and less cleaning thanks to the oscillating segments. - Comfort ash box as standard for dust-free ash removal

The ash box enables dust-free ash removal in compostable corn starch sacks. The boiler signals automatically when the box is full. - Intelligent fill level monitoring (optional)

Automatic sending of an order email to pellet suppliers can prevent stocks from running out.